Business Content

Utilize technology obtained from strict standards and management, we offer and provide reliable easy-to-use "shape" design and production

3 unique strengths of TOKAI RESIN

"the concept" becomes "the product “, we take the first step toward realization

【1】Shorter Lead Time

Simultaneous 5-axis machining performed

by FOOKE's ENDURA machine

significantly reduces product machining time.

【2】Design

In-house implementation from mechanical design,

3D modeling design to NC processing data.

Proposing gauges and jigs that are the most suitable

for customer needs and requests.

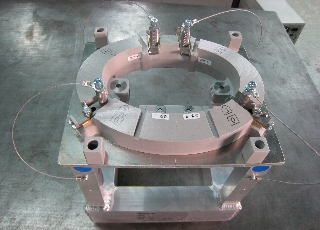

【3】Production Results

Produced inspection gauges and jigs for various industries and fields.

Some of past proposed cases are shown.

Main products based on our original technology

Using our original technology, we change customer’s “cannot do” into “can do”, those lead reduction of costs and work by various aspects