【Ⅰ】Production of various inspection jigs

We are good at aluminum processing such as argon welding.

It was one of the first in the jig industry to adopt aluminum,

and it is highly evaluated for its lightness, cleanliness, and work efficiency.

High accuracy and ease of use are guaranteed because the inspection surface

made with resin is processed with 5-axis NC even for complicated shapes.

Introducing some of products that show our technology.

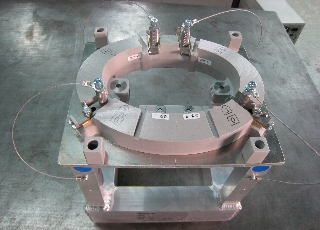

1.Sensor gauge

The inspection gauge attaching our original sensor measures and judges “pass / fail” instantly.

It makes to contribute quality improvement.

We have over 30 years experience on business with major companies.

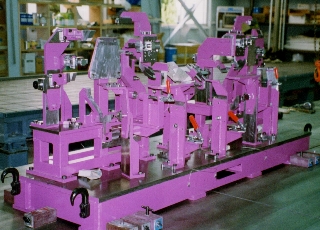

2.Assemble sensor jig

The jig with air push-up system attaching our original sensor makes to contribute quality improvement, shorter work time, and reducing costs to automotive manufacturers.

3.Heat-resistant gauge

Using inorganic heat-resistant materials developed by our company, we are able to reduce the cost of large-scale molding in a high-temperature kiln, which is greatly appreciated by our customers.

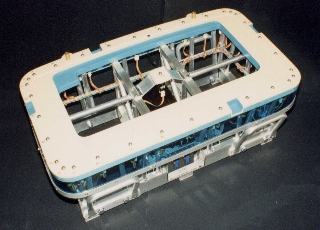

【Ⅱ】Production of automation・labor-saving devices

Design and production automation and labor-saving equipment such as

control and measurement combining electrical and electronic equipment.

【Ⅲ】Maintenance of milling machines